A Longitudinal Seam Welding Machine is a surprisingly efficient commercial solution used to weld instantly seams on cylindrical or flat sheet steel workpieces. This device plays an important role in production industries wherein non-stop, precise, and robust welds are required. It is mainly crucial for growing merchandise together with pipes, tanks, vessels, and automobile additives. The era in the back of longitudinal seam welding specializes in handing over clean, correct welds even as making sure constant best in the course of the manufacturing method.

Working Principle

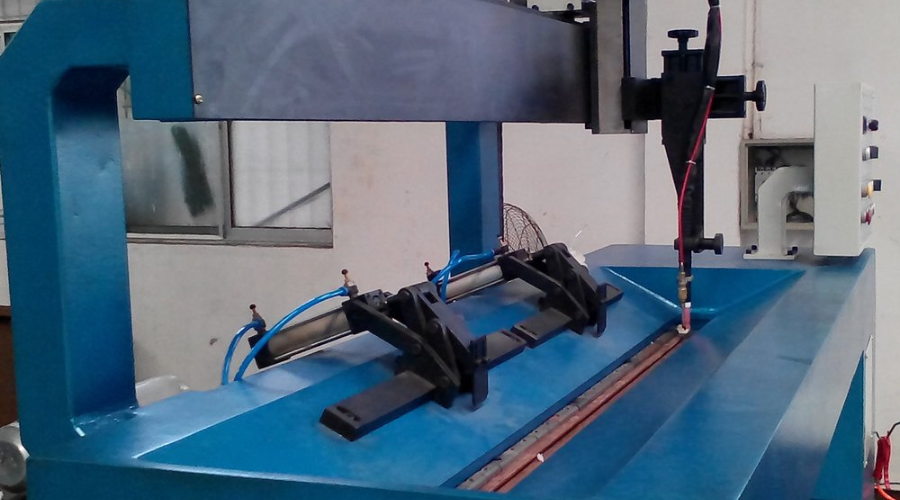

The Longitudinal Seam Welding Machine in China works at the precept of clamping the workpiece securely along its duration and applying strain at the same time as warmness is generated thru one of a kind welding techniques, including resistance welding, TIG, MIG, or plasma welding. The device guarantees that the seam is welded uniformly without gaps or susceptible spots. This makes it mainly beneficial for programs that demand high energy and leak-proof overall performance. The technique eliminates inconsistencies and offers an easy end alongside the welded seam.

Applications in Industry

Industries throughout various sectors rely upon Longitudinal Seam Welding Machine for his or her versatility. Within the automotive industry, they are used to fabricate fuel tanks, exhaust systems, and other additives that require robust, sealed seams. The aerospace quarter benefits from these machines to create excessive-precision components that have to resist pressure and pressure. Inside the production of pipelines, strain vessels, and storage tanks, longitudinal seam welding ensures that the joints are durable and able to deal with fluids or gases without leakage. The machine additionally finds applications in customer items manufacturing, wherein cylindrical or tubular components need dependable welding answers.

Advantages of Longitudinal Seam Welding

The system is designed to offer consistency, pace, and precision. Unlike manual welding, which can be vulnerable to mistakes and variations, longitudinal seam welding machines guarantee an extraordinary result on every occasion. They can deal with an extensive variety of metals which includes chrome steel, aluminum, and moderate steel, permitting manufacturers flexibility in production. The automated nature of the gadget reduces hard work expenses while increasing output, making it an economical preference for massive-scale operations. Moreover, the welds produced are clean and aesthetically appealing, which is usually a requirement in industries in which the end of the product is important.

Technological Innovations

Longitudinal Seam Welding Machine Supplier in China come geared up with advanced functions which include automated control systems, programmable parameters, and superior cooling systems. These innovations permit operators to attain unique results regardless of complicated welding duties. Some machines additionally integrate real-time monitoring systems that make certain constant weld nice by means of detecting and correcting any deviations at some point of the welding manner. The development of energy-efficient systems has similarly stepped forward the overall performance of these machines even as reducing operational prices.

Conclusion

Longitudinal Seam Welding Machine Manufacturer in China is an essential asset in industrial production, presenting unmatched precision, durability, and reliability for welding packages. Its capability to provide continuous and ideal welds makes it crucial in industries where first-class and electricity cannot be compromised. As technology keeps conforming, these machines are getting even more green and person-pleasing, in addition enhancing their role in modern manufacturing techniques.